×

×

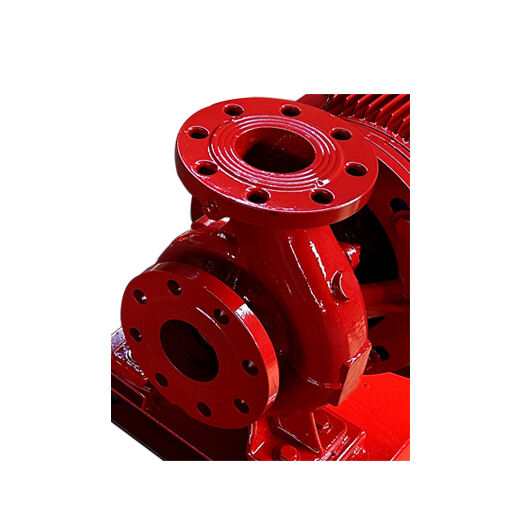

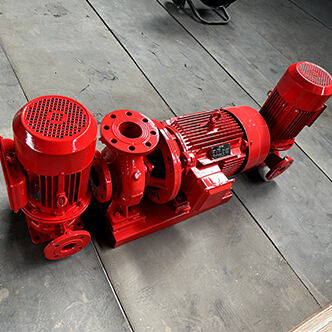

Electric in-line end suction pumps include vertical tube-feed centrifugal pumps and horizontal clean water pumps.

The vertical pipe-feed centrifugal pump has a compact structure, small footprint, stable operation, low vibration and low noise. It is easy to install and repair without dismantling the pipeline system. It is suitable for industrial and urban water supply and drainage, high-rise building pressurized water supply, garden sprinkler irrigation, fire fighting pressurization, long-distance transportation, and the operating temperature is T﹤80℃.

Horizontal clean water pump, used for conveying clean water and other liquids with chemical properties similar to clean water. The absolute concentricity of the pump shaft and the excellent dynamic and static balance of the impeller ensure smooth operation without vibration. In addition, it is very convenient to replace seals and bearings. It is suitable for industrial and urban water supply and drainage, fire boosting, long-distance transportation, HVAC refrigeration cycle, and the operating temperature is ≤80℃.

Please contact us to serve you!" >

Please contact us to serve you!" >

Fast Delivery

Stock products 3 days

Customized products: 15 days

After Sale Services

We offer 36 months warranty

OEM&ODM Available

We accept OEM&ODM for any quantity

Customize Capability

All materials customizable

All capabilities customizable

Service Support

Non-disclosure agreement

Good sealing performance

Alloy seals of different materials are used to transport different media without leakage

General Information:

| Place of Origin: | China |

| Brand Name: | Bei Gong |

| Model Number: | BGG20-1 |

| Certification: | CE ISO9001 |

Commerce Clause:

| Minimum Order Quantity: | 1 set |

| Price: | The product is customized and the actual transaction price shall prevail. |

| Packaging Details: | Export wooden box |

| Delivery Time: | The product is a customized product, and the actual delivery time shall prevail |

| Payment Terms: | T/T |

| Supply Ability: | 1000PCS |

The water outlet has a large diameter, is easy to use, and can withstand high pressure

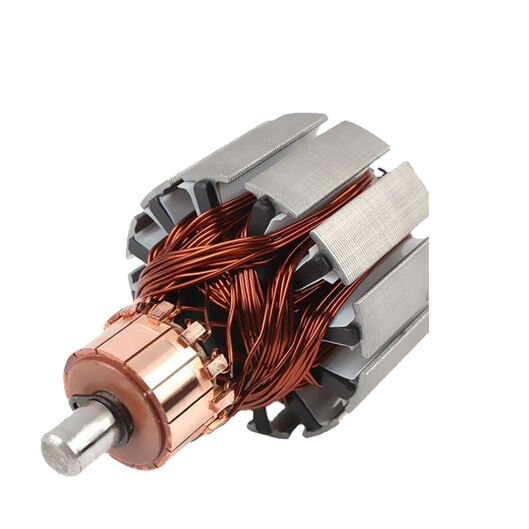

Selected raw material bearing steel, high temperature resistance, lower noise and long life

National standard pure copper movement, strong power, overload protection, reliable quality, and a variety of motors to choose from

Anti-corrosion and pressure-resistant, safer to use

Double-face alloy mechanical seals have good oxygen resistance, aging resistance, durability and wear resistance

Forest fire fighting

Building Fire Fighting

Traffic accident firefighting

Building pressurized water supply

Garden Sprinkler Irrigation

Urban water supply and drainage

| Performance parameter table | ||||||||||

| Model |

Flow (m³/h) |

Flow (GPM) |

Head (m) |

Pressure (bar) |

Efficiency (%) |

Speed (r/min) |

Power (kw) |

Power (HP) |

NPSH (M) |

Weight (kg) |

| 25-125 | 2.8 | 12 | 20.6 | 2.1 | 28 | 2900 | 0.75 | 1 | 2.3 | 28 |

| 4 | 18 | 20 | 2.0 | 36 | ||||||

| 5.2 | 23 | 18 | 1.8 | 35 | ||||||

| 25-125A | 2.5 | 11 | 17 | 1.7 | 35 | 2900 | 0.55 | 0.75 | 2.3 | 27 |

| 3.6 | 16 | 16 | 1.6 | |||||||

| 4.6 | 20 | 14.4 | 1.4 | |||||||

| 25-160 | 2.8 | 12 | 33 | 3.3 | 24 | 2900 | 1.5 | 2 | 2.3 | 39 |

| 4 | 18 | 32 | 3.2 | 32 | ||||||

| 5.2 | 23 | 30 | 3.0 | 33 | ||||||

| 25-160A | 2.6 | 11 | 29 | 2.9 | 31 | 2900 | 1.1 | 1.5 | 2.3 | 34 |

| 3.7 | 16 | 28 | 2.8 | |||||||

| 4.9 | 22 | 26 | 2.6 | |||||||

| 32-100 | 3.5 | 15 | 14.5 | 1.5 | 35 | 2900 | 0.55 | 0.75 | 2 | 27 |

| 4.5 | 20 | 12.5 | 1.3 | 44 | ||||||

| 5.3 | 23.32 | 11 | 1.1 | 38 | ||||||

| 32-100(I) | 4.4 | 19 | 13.2 | 1.3 | 48 | 2900 | 0.75 | 1 | 2 | 32 |

| 6.3 | 28 | 12.5 | 1.3 | 54 | ||||||

| 8.3 | 37 | 11.3 | 1.1 | 53 | ||||||

| 32-125 | 3.5 | 15 | 22 | 2.2 | 40 | 2900 | 0.75 | 1 | 2.3 | 28 |

| 5 | 22 | 20 | 2.0 | 44 | ||||||

| 6.5 | 29 | 18 | 1.8 | 42 | ||||||

| 32-125A | 3.1 | 14 | 17.6 | 1.8 | 43 | 2900 | 0.55 | 0.75 | 2.3 | 28 |

| 4.5 | 20 | 16 | 1.6 | |||||||

| 5.8 | 26 | 14.4 | 1.4 | |||||||

| 32-160 | 4.4 | 19 | 28 | 2.8 | 40 | 2900 | 1.5 | 2 | 2.3 | 39 |

| 6.5 | 29 | 32 | 3.2 | 44 | ||||||

| 5.8 | 25.52 | 30 | 3 | 42 | ||||||

| 32-160A | 2.8 | 12.32 | 27 | 2.7 | 31 | 2900 | 1.1 | 1.5 | 2 | 38 |

| 4 | 18 | 25 | 2.5 | 34 | ||||||

| 5.2 | 22.88 | 21 | 2.1 | 32 | ||||||

| 32-160(I) | 4.4 | 19 | 33.2 | 3.3 | 34 | 2900 | 2.2 | 3 | 2 | 47 |

| 6.3 | 28 | 32 | 3.2 | 40 | ||||||

| 8.3 | 37 | 30.2 | 3.0 | 42 | ||||||

| 32-200 | 3.1 | 14 | 50.5 | 5.1 | 28 | 2900 | 3 | 4 | 2 | 55 |

| 4.5 | 20 | 50 | 5.0 | 32 | ||||||

| 5.8 | 26 | 48 | 4.8 | 30 | ||||||

| 32-200(I) | 4.4 | 19 | 50.5 | 5.1 | 26 | 2900 | 4 | 5.5 | 2 | 43 |

| 6.3 | 28 | 50 | 5.0 | 33 | ||||||

| 8.3 | 37 | 48 | 4.8 | 35 | ||||||

| 32-200A | 2.8 | 12 | 44.6 | 4.5 | 34 | 2900 | 2.2 | 3 | 2 | 74 |

| 4 | 18 | 44 | 4.4 | 40 | ||||||

| 5.2 | 23 | 42.7 | 4.3 | 42 | ||||||

| 40-100 | 4.4 | 19 | 13.2 | 1.3 | 48 | 2900 | 0.55 | 0.75 | 2.3 | 32 |

| 6.3 | 28 | 12.5 | 1.3 | 54 | ||||||

| 8.3 | 37 | 11.3 | 1.1 | 53 | ||||||

| 40-100A | 3.9 | 17 | 10.6 | 1.1 | 52 | 2900 | 0.37 | 0.5 | 2.3 | 32 |

| 5.6 | 25 | 10 | 1.0 | |||||||

| 7.4 | 33 | 9 | 0.9 | |||||||

| 40-125 | 4.4 | 19 | 21 | 2.1 | 41 | 2900 | 1.1 | 1.5 | 2.3 | 34 |

| 6.3 | 28 | 20 | 2.0 | 46 | ||||||

| 8.3 | 37 | 18 | 1.8 | 43 | ||||||

| 40-125A | 3.9 | 17 | 17.6 | 1.8 | 40 | 2900 | 0.75 | 1 | 2.3 | 33 |

| 5.6 | 25 | 16 | 1.6 | 45 | ||||||

| 7.4 | 33 | 14.4 | 1.4 | 41 | ||||||

| 40-160 | 4.4 | 19 | 33 | 3.3 | 35 | 2900 | 2.2 | 3 | 2.3 | 47 |

| 6.3 | 28 | 32 | 3.2 | 40 | ||||||

| 8.3 | 37 | 30 | 3.0 | 40 | ||||||

| 40-160A | 4.1 | 18 | 29 | 2.9 | 34 | 2900 | 1.5 | 2 | 2.3 | 43 |

| 5.9 | 26 | 28 | 2.8 | 39 | ||||||

| 7.8 | 34 | 26.3 | 2.6 | 39 | ||||||

| 40-160B | 3.8 | 17 | 25.5 | 2.6 | 34 | 2900 | 1.1 | 1.5 | 2.3 | 38 |

| 5.5 | 24 | 24 | 2.4 | 38 | ||||||

| 7.2 | 32 | 22.5 | 2.3 | 37 | ||||||

| 40-200 | 4.4 | 19 | 51 | 5.1 | 26 | 2900 | 4 | 5.5 | 2.3 | 74 |

| 6.3 | 28 | 50 | 5.0 | 33 | ||||||

| 8.3 | 37 | 48 | 4.8 | 32 | ||||||

| 40-200A | 4.1 | 18 | 45 | 4.5 | 26 | 2900 | 3 | 4 | 2.3 | 62 |

| 5.9 | 26 | 44 | 4.4 | 31 | ||||||

| 7.8 | 34 | 42 | 4.2 | 30 | ||||||

For more detailed product parameters, please consult customer service.

Expand all

Copyright © Hebei Beigong Pump Co., Ltd. All Rights Reserved - Privacy Policy