×

×

The design of the single-stage single-suction fluoroplastic alloy chemical centrifugal pump combines international standards and non-metallic pump technology, using a metal shell lined with polyperfluoroethylene propylene (F46).

The pump cover, impeller and sleeve are all made of metal inserts wrapped in fluoroplastics and sintered and pressed as a whole.

The shaft seal adopts an external bellows mechanical seal, which is not only corrosion-resistant and wear-resistant, but also has excellent sealing performance.

The inlet and outlet of the pump are reinforced with cast steel to enhance pressure resistance.

The pump is widely used in the transportation of corrosive media in chemical production.

Please contact us to serve you!" >

Please contact us to serve you!" >

Fast Delivery

Stock products: 3 days

Customized products: 15 days

After Sale Services

We offer 36 months warranty

OEM&ODM Available

We accept OEM&ODM for any quantity

Customize Capability

All materials customizable

All capabilities customizable

Service Support

Non-disclosure agreement

24-hour online video call after-sales service

Good sealing performance

Alloy seals of different materials are used to transport different media without leakage

General Information:

| Place of Origin: | China |

| Brand Name: | Bei Gong |

| Model Number: | BGLXB |

| Certification: | CE ISO9001 |

Commerce Clause:

| Minimum Order Quantity: | 1 set |

| Price: | The product is customized and the actual transaction price shall prevail. |

| Packaging Details: | Export wooden box |

| Delivery Time: | The product is a customized product, and the actual delivery time shall prevail |

| Payment Terms: | T/T |

| Supply Ability: | 1000PCS |

The pump body adopts metal shell and fluoroplastic lining, which is resistant to high temperature and corrosion

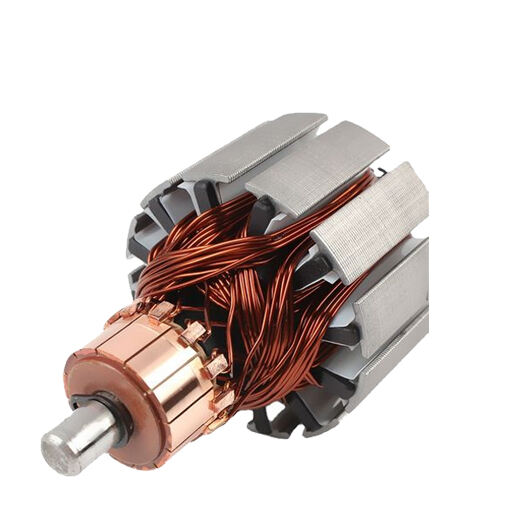

National standard pure copper movement, strong power, overload protection, reliable quality

High temperature resistant, T-shaped taper, corrosion resistant, wear resistant, not easy to deform

The shaft seal adopts advanced WB2 type external bellows mechanical seal with reliable sealing performance

High efficiency, energy saving, low vibration, low noise, reliable performance

Chemical Industry

Metal smelting

Automobile manufacturing

Pharmaceuticals

Oil industry

Electrical power

| Performance parameter table | ||||||||

| Model |

Flow (m³/h) |

Flow (GPM) |

Head (m) |

Pressure (bar) |

Speed (r/min) |

Power Motor (kw) |

Power (HP) |

Efficiency (%) |

| 32-25-125 | 5 | 22 | 20 | 2 | 2900 | 1.5 | 2 | 30 |

| 32-25-160 | 5 | 22 | 25 | 2.5 | 2900 | 2.2 | 3 | 28 |

| 40-32-125 | 8 | 35 | 20 | 2 | 2900 | 2.2 | 3 | 35 |

| 40-32-160 | 8 | 35 | 32 | 3.2 | 2900 | 3 | 4 | 32 |

| 50-32-125 | 12.5 | 55 | 250 | 25 | 2900 | 3 | 4 | 51 |

| 50-32-160 | 6.3 | 28 | 5 | 0.5 | 1450 | 0.55 | 1 | 45 |

| 12.5 | 55 | 32 | 3.2 | 2900 | 4 | 5 | 46 | |

| 50-32-200 | 6.3 | 28 | 8 | 0.8 | 1450 | 0.55 | 1 | 40 |

| 12.5 | 55 | 50 | 5 | 2900 | 7.5 | 10 | 39 | |

| 65-50-125 | 6.3 | 28 | 12.5 | 1.3 | 1450 | 1.1 | 1 | 33 |

| 25 | 110 | 20 | 2 | 2900 | 4 | 5 | 61 | |

| 65-50-160 | 12.5 | 55 | 5 | 0.5 | 1450 | 0.55 | 1 | 54 |

| 25 | 110 | 32 | 3.2 | 2900 | 5.5 | 7 | 56 | |

| 65-40-200 | 12.5 | 55 | 8 | 0.8 | 1450 | 0.75 | 1 | 50 |

| 25 | 110 | 50 | 5 | 2900 | 11 | 15 | 51 | |

| 65-40-250 | 12.5 | 55 | 12.5 | 1.3 | 1450 | 1.5 | 2 | 45 |

| 25 | 110 | 80 | 8 | 2900 | 18.5 | 25 | 45 | |

| 80-65-125 | 12.5 | 55 | 20 | 2 | 1450 | 3 | 4 | 38 |

| 50 | 220 | 20 | 2 | 2900 | 15.5 | 20 | 65 | |

| 80-65-160 | 25 | 110 | 5 | 0.5 | 1450 | 0.75 | 1 | 60 |

| 50 | 220 | 32 | 3.2 | 2900 | 11 | 15 | 64 | |

| 80-50-200 | 25 | 110 | 8 | 0.8 | 1450 | 1.5 | 2 | 59 |

| 50 | 220 | 50 | 5 | 2900 | 15 | 20 | 63 | |

| 80-50-250 | 25 | 110 | 12.5 | 1.3 | 1450 | 2.2 | 3 | 57 |

| 50 | 220 | 80 | 8 | 2900 | 30 | 40 | 51 | |

| 100-80-125 | 25 | 110 | 20 | 2 | 1450 | 4 | 5 | 44 |

| 100 | 440 | 20 | 2 | 2900 | 11 | 15 | 72 | |

| 100-80-160 | 50 | 220 | 5 | 0.5 | 1450 | 1.5 | 2 | 70 |

| 100 | 440 | 32 | 3.2 | 2900 | 18.5 | 25 | 70 | |

| 100-65-200 | 50 | 220 | 8 | 0.8 | 1450 | 2.2 | 3 | 66 |

| 100 | 440 | 50 | 5 | 2900 | 30 | 40 | 68 | |

| 100-65-250 | 50 | 220 | 12.5 | 1.3 | 1450 | 4 | 5 | 64 |

| 100 | 440 | 80 | 8 | 2900 | 45 | 60 | 66 | |

| 125-100-200 | 50 | 220 | 250 | 25 | 1450 | 7.5 | 10 | 62 |

| 200 | 880 | 50 | 5 | 2900 | 55 | 75 | 74 | |

| 125-100-250 | 100 | 440 | 12.5 | 1.3 | 1450 | 7.5 | 10 | 70 |

| 200 | 880 | 80 | 8 | 2900 | 90 | 120 | 72 | |

| 150-125-250 | 100 | 440 | 20 | 2 | 1450 | 11 | 15 | 70 |

| 150-125-315 | 200 | 880 | 32 | 3.2 | 1450 | 37 | 50 | 72 |

For more detailed product parameters, please consult customer service.

Expand all

Copyright © Hebei Beigong Pump Co., Ltd. All Rights Reserved - Privacy Policy